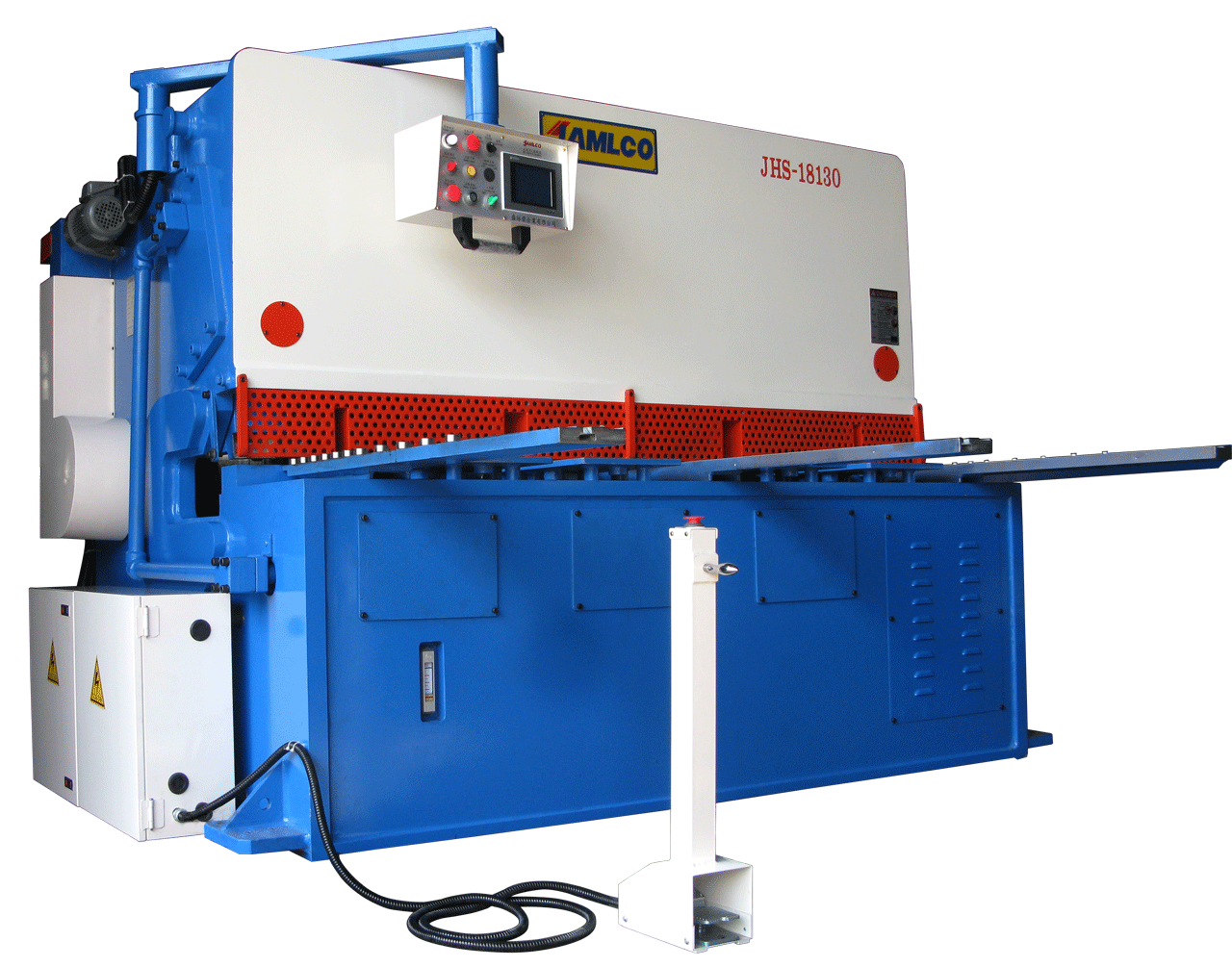

NC搖臂式油壓剪床特色

高剛性與強度

為了重負荷剪切需求,經應力消除處理且一體化結構的台面與特厚的機體框架,提供最大的剛性和強度。

氮氣回升缸:

為了重負荷剪切需求,經應力消除處理且一體化結構的台面與特厚的機體框架,提供最大的剛性和強度。

特殊的刀間隙調整裝置

刀間隙調整裝置以特殊設計360度旋轉偏心蝸桿蝸輪組驅動,調整範圍大於他牌油壓剪床。 即使刀具經多次研磨後而變薄的狀況下,在調整間隙時,刀具仍能緊貼刀座。 無需如他牌利用螺絲頂出刀具,藉以補償間隙調整行程不足問題,而提高刀具損傷的可能性(未緊貼刀座易斷裂)。

壓板缸(壓桿)

壓板方式採用集體回路及單桿油缸併排設計,與主油壓迴路串連,可依剪裁負荷自動調整壓桿出力,於鐵板不平時,壓板缸會壓緊在鐵板上以確保裁切精度。

線影裝置

剪切對線時,使用特殊的線影裝置,經燈光照射而成一直線之黑線投影於鐵板上,提高工作效率及準確性。

NC控制系統附觸控螢幕

後定規定位系統採伺服馬達驅動,精密滾珠螺桿傳動,經由人性化的觸控式人機介面作設定 ,尺寸定位精準確實,具有測試原點功能、簡易校正誤差值系統。人機介面亦有刀間隙調整、剪切計數等功能。

優勢

JHS系列NC搖臂式油壓剪床提供以下優勢:

- 以最大化壓板缸壓力確保高精度剪切

- 以特殊360度旋轉偏心蝸桿蝸輪設計達到簡單且準確的刀間隙調整

- 使用高品質氮氣缸作為回升缸,提升機器操作的安全性和效率。

- 便利的觸控式螢幕控制,方便調整設定。

- 使用線影快速地視覺化定位經標記畫線的板材

選擇JHS系列NC搖臂式油壓剪床,以獲得高品質且可靠的剪切成果。

規格:

| Model | Capacity(mm) | Rake Angle | S.P.M. | Back Gauge (mm) | Front Gauge (mm) | Motor (HP) | Dimension (mm) | Weight (ton) |

|---|---|---|---|---|---|---|---|---|

| JHS-1565 | 6.5 x 1550 | 1° 30’ | 23-45 | 950 | 1300 | 15 | 2400X2100X1750 | 4.5 |

| JHS-1595 | 9.5 x 1550 | 1° 30’ | 14-28 | 950 | 1300 | 20 | 2400X2150X1950 | 7.2 |

| JHS-15130 | 13 x 1550 | 2° | 9-15 | 950 | 1300 | 30 | 2500X2250X2050 | 8 |

| JHS-15160 | 16 x 1550 | 2° 30’ | 9-15 | 950 | 1300 | 40 | 2500X2250X2100 | 10.3 |

| JHS-15190 | 19 x 1550 | 3° | 8-13 | 950 | 1300 | 40 | 2550X2300X2150 | 12.8 |

| JHS-1865 | 6.5 x 1850 | 1° 30’ | 20-40 | 950 | 1300 | 15 | 2650X2100X1800 | 5.3 |

| JHS-1895 | 9.5 x 1850 | 1° 30’ | 12-24 | 950 | 1300 | 20 | 2650X2150X1950 | 8 |

| JHS-18130 | 13 x 1850 | 2° | 13-24 | 950 | 1300 | 30 | 2750X2250X2100 | 9 |

| JHS-18160 | 16 x 1850 | 2° 30’ | 9-15 | 950 | 1300 | 40 | 2850X2300X2150 | 11.6 |

| JHS-18190 | 19 x 1850 | 3° | 8-13 | 950 | 1300 | 40 | 2900X2350X2250 | 14.5 |

| JHS-2565 | 6.5 x 2500 | 1° 30’ | 16-32 | 950 | 1300 | 15 | 3300X2150X1900 | 6.8 |

| JHS-2595 | 9.5 x 2500 | 1° 30’ | 13-25 | 950 | 1300 | 20 | 3350X2200X2050 | 9.2 |

| JHS-25130 | 13 x 2500 | 2° | 13-24 | 950 | 1300 | 40 | 3400X2300X2200 | 12 |

| JHS-25160 | 16 x 2500 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 3550X2400X2550 | 15 |

| JHS-25190 | 19 x 2500 | 3° | 8-13 | 950 | 1300 | 75 | 3600X2500X2800 | 17.5 |

| JHS-3165 | 6.5 x 3100 | 1° 30’ | 14-23 | 950 | 1300 | 15 | 3850X2150X1950 | 8.3 |

| JHS-3195 | 9.5 x 3100 | 2° | 12-22 | 950 | 1300 | 25 | 3900X2200X2100 | 11.2 |

| JHS-31130 | 13 x 3100 | 2° 30’ | 13-24 | 950 | 1300 | 40 | 3950X2300X2250 | 14.8 |

| JHS-31160 | 16 x 3100 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 4200X2450X2600 | 18 |

| JHS-31190 | 19 x 3100 | 3° | 8-13 | 950 | 1300 | 75 | 4250X2650X2900 | 18 |

| JHS-31220 | 22 x 3100 | 4° | 8-12 | 950 | 1300 | 75 | 4300X2700X3050 | 29 |

| JHS-31250 | 25 x 3100 | 4° | 8-12 | 950 | 1300 | 75 | 4450X2800X3200 | 35 |

| JHS-3765 | 6.5 x 3700 | 1° 30’ | 13-22 | 950 | 1300 | 20 | 4500X2150X1950 | 12.2 |

| JHS-3795 | 9.5 x 3700 | 1° 30’ | 11-21 | 950 | 1300 | 30 | 4550X2250X2150 | 14.7 |

| JHS-37130 | 13 x 3700 | 2° | 14-23 | 950 | 1300 | 40 | 4600X2350X2250 | 18.1 |

| JHS-37160 | 16 x 3700 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 4650X2500X2700 | 24 |

| JHS-37190 | 19 x 3700 | 3° | 8-13 | 950 | 1300 | 75 | 4700X2600X2900 | 28 |

| JHS-4165 | 6.5 x 4100 | 1° 30’ | 12-20 | 950 | 1300 | 20 | 4900X2200X2100 | 12 |

| JHS-4195 | 9.5 x 4100 | 1° 30’ | 11-21 | 950 | 1300 | 30 | 4950X2300X2250 | 19.5 |

| JHS-41130 | 13 x 4100 | 2° | 12-22 | 950 | 1300 | 50 | 5000X2400X2400 | 26 |

| JHS-41160 | 16 x 4100 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 5200X2700X2750 | 28 |

| JHS-41190 | 19 x 4100 | 3° | 8-13 | 950 | 1300 | 75 | 5250X2800X2950 | 32 |

| JHS-5165 | 6.5 x 5100 | 1° 30’ | 11-18 | 950 | 1300 | 25 | 6000X2750X3050 | 18 |

| JHS-5195 | 9.5 x 5100 | 1° 30’ | 9-18 | 950 | 1300 | 40 | 6150X2800X3200 | 26 |

| JHS-51130 | 13 x 5100 | 2° | 10-20 | 950 | 1300 | 50 | 6200X2900X3300 | 33 |

| JHS-51160 | 16 x 5100 | 2° 30’ | 8-18 | 950 | 1300 | 60 | 6350X2900X2850 | 35 |

| JHS-51190 | 19 x 5100 | 3° | 10-20 | 950 | 1300 | 75 | 6400X2900X3000 | 42 |

| JHS-6265 | 6.5 x 6200 | 1° 30’ | 9-16 | 950 | 1300 | 25 | 7200X2800X3150 | 26 |

| JHS-6295 | 9.5 x 6200 | 1° 30’ | 7-16 | 950 | 1300 | 40 | 7250X2900X3200 | 40 |

| JHS-62130 | 13 x 6200 | 2° | 8-18 | 950 | 1300 | 50 | 7300X2950X3300 | 50 |

| JHS-62160 | 16 x 6200 | 2° 30’ | 7-16 | 950 | 1300 | 75 | 7350X3050X3400 | 53 |

| JHS-62190 | 19 x 6200 | 3° | 8-12 | 950 | 1300 | 75 | 7400X3200X3550 | 55 |