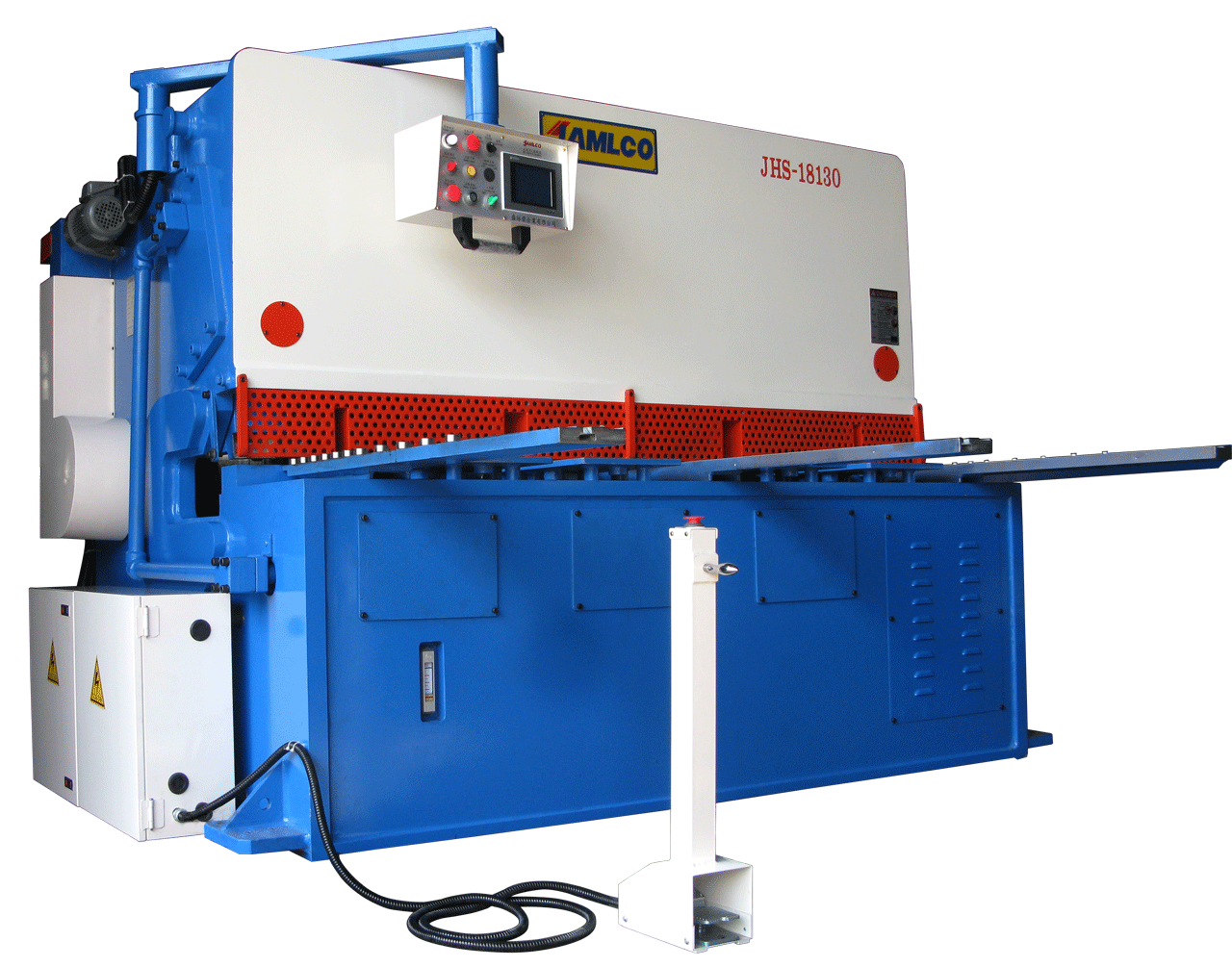

Features of our NC Hydraulic Swing Beam Shear

-

High Stiffness and Strength:

The stress-relieved, unitized box construction of the table and extra-thick steel frames provides maximum stiffness and strength for heavy-duty cutting.

-

Logic Hydraulic Circuit System:

Our swing beam shear has a hydraulic system comprised of long life, heavy-duty components and is controlled by sequence valves. This system is easy to access and service.

-

Nitrogen Cylinders:

The return cylinders of our swing beam shear are made of nitrogen cylinders that are independent from the hydraulic cylinders. These cylinders automatically retract the blade to the top of the stroke position during power shut-down, emergency, or after the cutting stroke is completed. They improve the safety and efficiency of the machine operation.

-

Special Blade Clearance Adjustment:

Our shearing machine’s special blade clearance adjustment, driven by worm gear sets of a unique 360-degree-turning eccentric design, enhances the efficiency of blade clearance adjustment. With a conveniently located adjustment on the touch screen, operators can accurately adjust the blade clearance on both sides of the machine simultaneously. Our machine’s longer stroke distance prevents top knife breakage, unlike other brands with limited stroke distance and use of sector gear sets, which can lead to difficulty in adjusting clearance after grinding knives several times and risking top knife breakage if not tightly secured to the base.

-

Hold Downs:

The hold downs of our swing beam shear are synchronized with the upper blade travel to provide maximum hold down pressure at the moment of shearing, thus, assuring cutting accuracy. As shearing forces on the plate increase, the hold down pressure increases to provide optimum gripping action.

-

Shadow Line for Accurate Shearing:

For fast, visual positioning of sheets with scribed lines or punch marks, an intense light is provided. The light source casts a precise shadow line for accurate positioning and shearing.

-

NC Control System with LCD Touch Screen:

The new 5.7 inch LCD touch screen controls settings for the blade gap adjustment, length of stroke, back gauge setting (mm) and number of cuts.

Benefits

Our NC Hydraulic Swing Beam Shear offers the following benefits:

- High accuracy cutting with maximum hold down pressure

- Easy and precise blade clearance adjustment with the worm gear sets of special 360-degree-turning eccentric design

- Improved safety and efficiency of machine operation with the use of nitrogen cylinders as return cylinders

- Conveniently located touch screen controls for easy settings adjustment

- Fast, visual positioning of sheets with scribed lines or punch marks with the provided intense light

Choose the NC Hydraulic Swing Beam Shear for high quality and reliable cutting results.

Specificaion:

| Model | Capacity(mm) | Rake Angle | S.P.M. | Back Gauge (mm) | Front Gauge (mm) | Motor (HP) | Dimension (mm) | Weight (ton) |

|---|---|---|---|---|---|---|---|---|

| JHS-1565 | 6.5 x 1550 | 1° 30’ | 23-45 | 950 | 1300 | 15 | 2400X2100X1750 | 4.5 |

| JHS-1595 | 9.5 x 1550 | 1° 30’ | 14-28 | 950 | 1300 | 20 | 2400X2150X1950 | 7.2 |

| JHS-15130 | 13 x 1550 | 2° | 9-15 | 950 | 1300 | 30 | 2500X2250X2050 | 8 |

| JHS-15160 | 16 x 1550 | 2° 30’ | 9-15 | 950 | 1300 | 40 | 2500X2250X2100 | 10.3 |

| JHS-15190 | 19 x 1550 | 3° | 8-13 | 950 | 1300 | 40 | 2550X2300X2150 | 12.8 |

| JHS-1865 | 6.5 x 1850 | 1° 30’ | 20-40 | 950 | 1300 | 15 | 2650X2100X1800 | 5.3 |

| JHS-1895 | 9.5 x 1850 | 1° 30’ | 12-24 | 950 | 1300 | 20 | 2650X2150X1950 | 8 |

| JHS-18130 | 13 x 1850 | 2° | 13-24 | 950 | 1300 | 30 | 2750X2250X2100 | 9 |

| JHS-18160 | 16 x 1850 | 2° 30’ | 9-15 | 950 | 1300 | 40 | 2850X2300X2150 | 11.6 |

| JHS-18190 | 19 x 1850 | 3° | 8-13 | 950 | 1300 | 40 | 2900X2350X2250 | 14.5 |

| JHS-2565 | 6.5 x 2500 | 1° 30’ | 16-32 | 950 | 1300 | 15 | 3300X2150X1900 | 6.8 |

| JHS-2595 | 9.5 x 2500 | 1° 30’ | 13-25 | 950 | 1300 | 20 | 3350X2200X2050 | 9.2 |

| JHS-25130 | 13 x 2500 | 2° | 13-24 | 950 | 1300 | 40 | 3400X2300X2200 | 12 |

| JHS-25160 | 16 x 2500 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 3550X2400X2550 | 15 |

| JHS-25190 | 19 x 2500 | 3° | 8-13 | 950 | 1300 | 75 | 3600X2500X2800 | 17.5 |

| JHS-3165 | 6.5 x 3100 | 1° 30’ | 14-23 | 950 | 1300 | 15 | 3850X2150X1950 | 8.3 |

| JHS-3195 | 9.5 x 3100 | 2° | 12-22 | 950 | 1300 | 25 | 3900X2200X2100 | 11.2 |

| JHS-31130 | 13 x 3100 | 2° 30’ | 13-24 | 950 | 1300 | 40 | 3950X2300X2250 | 14.8 |

| JHS-31160 | 16 x 3100 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 4200X2450X2600 | 18 |

| JHS-31190 | 19 x 3100 | 3° | 8-13 | 950 | 1300 | 75 | 4250X2650X2900 | 18 |

| JHS-31220 | 22 x 3100 | 4° | 8-12 | 950 | 1300 | 75 | 4300X2700X3050 | 29 |

| JHS-31250 | 25 x 3100 | 4° | 8-12 | 950 | 1300 | 75 | 4450X2800X3200 | 35 |

| JHS-3765 | 6.5 x 3700 | 1° 30’ | 13-22 | 950 | 1300 | 20 | 4500X2150X1950 | 12.2 |

| JHS-3795 | 9.5 x 3700 | 1° 30’ | 11-21 | 950 | 1300 | 30 | 4550X2250X2150 | 14.7 |

| JHS-37130 | 13 x 3700 | 2° | 14-23 | 950 | 1300 | 40 | 4600X2350X2250 | 18.1 |

| JHS-37160 | 16 x 3700 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 4650X2500X2700 | 24 |

| JHS-37190 | 19 x 3700 | 3° | 8-13 | 950 | 1300 | 75 | 4700X2600X2900 | 28 |

| JHS-4165 | 6.5 x 4100 | 1° 30’ | 12-20 | 950 | 1300 | 20 | 4900X2200X2100 | 12 |

| JHS-4195 | 9.5 x 4100 | 1° 30’ | 11-21 | 950 | 1300 | 30 | 4950X2300X2250 | 19.5 |

| JHS-41130 | 13 x 4100 | 2° | 12-22 | 950 | 1300 | 50 | 5000X2400X2400 | 26 |

| JHS-41160 | 16 x 4100 | 2° 30’ | 9-15 | 950 | 1300 | 60 | 5200X2700X2750 | 28 |

| JHS-41190 | 19 x 4100 | 3° | 8-13 | 950 | 1300 | 75 | 5250X2800X2950 | 32 |

| JHS-5165 | 6.5 x 5100 | 1° 30’ | 11-18 | 950 | 1300 | 25 | 6000X2750X3050 | 18 |

| JHS-5195 | 9.5 x 5100 | 1° 30’ | 9-18 | 950 | 1300 | 40 | 6150X2800X3200 | 26 |

| JHS-51130 | 13 x 5100 | 2° | 10-20 | 950 | 1300 | 50 | 6200X2900X3300 | 33 |

| JHS-51160 | 16 x 5100 | 2° 30’ | 8-18 | 950 | 1300 | 60 | 6350X2900X2850 | 35 |

| JHS-51190 | 19 x 5100 | 3° | 10-20 | 950 | 1300 | 75 | 6400X2900X3000 | 42 |

| JHS-6265 | 6.5 x 6200 | 1° 30’ | 9-16 | 950 | 1300 | 25 | 7200X2800X3150 | 26 |

| JHS-6295 | 9.5 x 6200 | 1° 30’ | 7-16 | 950 | 1300 | 40 | 7250X2900X3200 | 40 |

| JHS-62130 | 13 x 6200 | 2° | 8-18 | 950 | 1300 | 50 | 7300X2950X3300 | 50 |

| JHS-62160 | 16 x 6200 | 2° 30’ | 7-16 | 950 | 1300 | 75 | 7350X3050X3400 | 53 |

| JHS-62190 | 19 x 6200 | 3° | 8-12 | 950 | 1300 | 75 | 7400X3200X3550 | 55 |