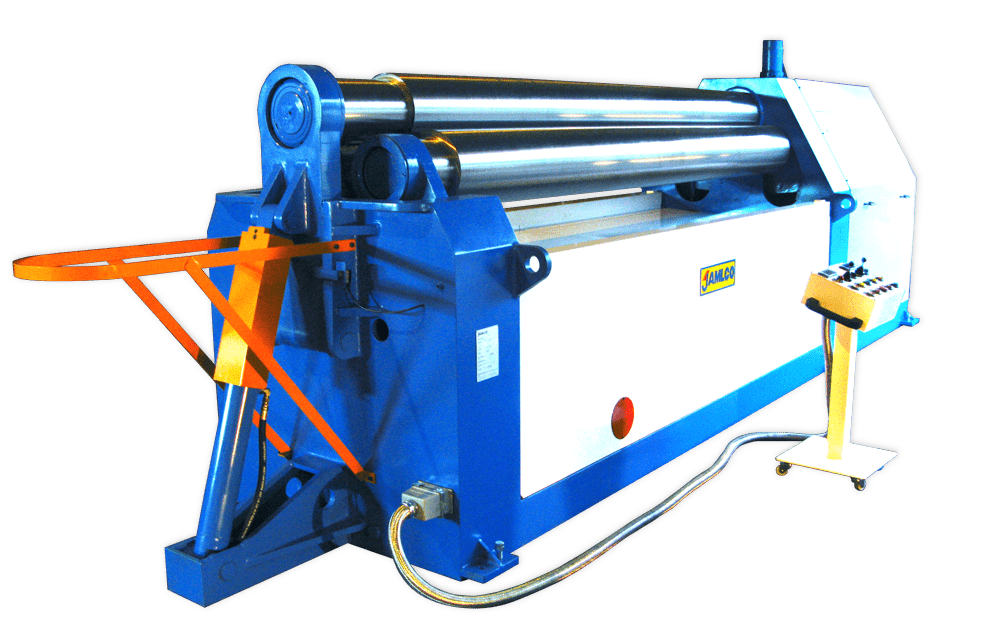

Built to handle a wide range of materials and thicknesses, our Hydraulic 3-roll Plate Bending Rolls (Double-pinch type) machines offer precision bending and efficient production to help you get the job done right.

Features of our Double-pinch Plate Bending Rolls:

Better Pre-Bending for Experts:

The double-pinch design of the machines ensures better pre-bending, as the top roll presses the plate between the two lower rolls, reducing the flat spots on the leading and trailing edges. Compared to initial-pinch machines, the advantage of double-pinch machines is that the operator doesn’t need to remove, flip, and re-square the plate after prebending.

Increased Precision:

Three-roll, double-pinch roll bending machines offer increased precision in bending due to their design equipped with digital readouts and advanced control systems for the bottom two rolls, allowing for precise control and measurement, and feature polished finish rolls to reduce friction and improve the quality of finished products.

Improved Efficiency:

Our machines feature a hydraulic drop end for easy removal of finished products and reduced risk of damage to the machine or materials. It feature faster cycle times and higher production capacities due to a movable control panel for improved ergonomics and powerful hydraulic system, leading to improved efficiency and productivity in your fabrication needs.

Versatility:

Three-roll, double-pinch roll bending machines offer greater versatility in bending a wide range of materials and thicknesses, including cone rolling, making them adaptable to various applications.

Enhanced Safety:

These machines are designed with built-in safety features, such as emergency stop buttons, guards and overload protection, ensuring the safety of operators during operation.

Customizable Options:

Our three-roll, double-pinch machines are available with a variety of customizable options, allowing you to tailor the machine to your specific needs and requirements.

Our three-roll, double-pinch machines are the perfect addition to your fabrication shop, offering precision, efficiency, and versatility. With customizable options and built-in safety features, our machines are designed to meet the unique needs of your business.

| MODEL | Capacity (mm) | ROLL Dia. (mm) | Min. Rolling Dia. (mm) | Motor (HP) | Dimension (mm) | Weight (Kg) |

|---|---|---|---|---|---|---|

| JR-0613-3D | 13 x 2050 | 280 | 420 | 10 | 3400x1250x1500 | 7600 |

| JR-0616-3D | 16 x 2050 | 300 | 450 | 15 | 3850x1420x1680 | 8100 |

| JR-0620-3D | 20 x 2050 | 320 | 480 | 30 | 4200x1650x1850 | 10500 |

| JR-0625-3D | 25 x 2050 | 350 | 525 | 30 | 4500x1700x1860 | 11000 |

| JR-0630-3D | 30 x 2050 | 380 | 570 | 50 | 5000x2000x1900 | 13000 |

| JR-0635-3D | 35 x 2050 | 420 | 630 | 50 | 5000x2200x2000 | 16000 |

| JR-0813-3D | 13 x 2550 | 300 | 450 | 15 | 4450x1420x1680 | 9100 |

| JR-0816-3D | 16 x 2550 | 320 | 480 | 30 | 4700x1650x1860 | 11500 |

| JR-0820-3D | 20 x 2550 | 350 | 525 | 30 | 5000x1700x1860 | 12000 |

| JR-0825-3D | 25 x 2550 | 380 | 570 | 50 | 5500x2000x1900 | 15000 |

| JR-0830-3D | 30 x 2550 | 420 | 630 | 50 | 5500x2200x2000 | 18000 |

| JR-0835-3D | 35 x 2550 | 460 | 690 | 60 | 5500x2350x2300 | 23000 |

| JR-1013-3D | 13 x 3100 | 320 | 480 | 30 | 5200x1650x1860 | 13500 |

| JR-1016-3D | 16 x 3100 | 350 | 525 | 30 | 5500x1700x1860 | 14000 |

| JR-1020-3D | 20 x 3100 | 380 | 570 | 50 | 6000x2000x1900 | 17000 |

| JR-1025-3D | 25 x 3100 | 420 | 630 | 50 | 6000x2200x2000 | 21000 |

| JR-1030-3D | 30 x 3100 | 460 | 690 | 75 | 6000x2350x2300 | 25000 |

| JR-1035-3D | 35 x 3100 | 500 | 750 | 75 | 6200x2500x2800 | 35000 |

| JR-1413-3D | 13 x 4100 | 380 | 570 | 50 | 7000x1900x2000 | 20000 |

| JR-1416-3D | 16 x 4100 | 420 | 630 | 50 | 7000x2000x2200 | 23300 |

| JR-1420-3D | 20 x 4100 | 460 | 690 | 75 | 7000x2350x2300 | 32000 |

| JR-1425-3D | 25 x 4100 | 500 | 750 | 75 | 7200x2500x2800 | 40000 |